SAGMILLING.COM .:. Mill Critical Speed Determination

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's

consulter en ligne

Low SAG Mill Critical Speed - 911 Metallurgist

2023年6月23日 There are at least two critical changes to your throughput when lowering mill speed: Lower mill RPM = lower throughput due to lower circulation rate at critical

consulter en ligne

Research on performance of a laboratory-scale SAG mill

2022年7月1日 Here, the mill fraction of critical speed is the ratio of the actual speed of the mill to the critical speed, and the empirical formula [25] of the critical speed of the SAG

consulter en ligne

SAG Circuit Design - Crushing, Screening Conveying

2023年7月19日 Unfortunately I have a program for SAG mills and grinding circuits. Computational testing showed that: - Capacity of SAG Mills can increase to 10000 t/h. -

consulter en ligne

SAG Mill Grinding Circuit Design - 911 Metallurgist

2016年6月6日 Common convention generally refers to high-aspect ratio mills as SAG mills (with diameter to effective grinding length ratios of 3:1 to 1:1), low-aspect ratio mills (generally, a mill with a significantly longer

consulter en ligne

Modelling SAG milling power and specific energy

2015年1月1日 For example, for an 36′ × 17′ SAG Mill, with a power consumption of 11.7 MW, operating at 73% solids, 13.5% balls charge and at 76% of the critical speed, with

consulter en ligne

The Importance of Critical Speed Pumps Systems

2022年5月1日 Critical speed is the speed where the natural vibration (resonance) occurs. Resonance is when the unit has high vibration from a disproportionate (small) stimulus.

consulter en ligne

Sag for Speed Sailing World

2012年9月5日 Sag for Speed. Understanding the effects of forestay tension is key to getting the most out of your sail plan. From the Experts "Boatspeed" from our

consulter en ligne

Mill Speed - an overview ScienceDirect Topics

Autogenous and Semi-Autogenous Mills. In Mineral Processing Design and Operations (Second Edition), 2016. 9.3.4 Mill Speed. During normal operation the mill speed tends to vary with mill charge. According to available literature, the operating speeds of AG mills are much higher than conventional tumbling mills and are in the range of 80–85% of the

consulter en ligne

SAGMILLING.COM .:. Mill Critical Speed Determination

The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface. This is the rotational speed where balls will not fall away from the mill's shell. Mill Inside Diameter: Feet Metres. Enter the mill diameter inside the shell (excluding liners).

consulter en ligne

OPTIONS FOR LOW SPEED AND OPERATING SPEED

2020年4月29日 natural gravity sag of the rotor has no effect on the rotor balance. SHRUNK ON PARTS On most "built up" rotors, wheels, discs, impellers, sleeves are mounted on the shaft with a predetermined interference fit. The minimum is dictated by a requirement for metal to metal contact when at operating speed. Should a clearance exist at speed, the part

consulter en ligne

How to Calculate and Solve for Critical Mill of Speed Ball

2021年7月18日 The formula for calculating critical mill of speed: N c = 42.3 / √ (D – d) Where: N c = Critical Speed of Mill. D = Mill Diameter. d = Diameter of Balls. Let’s solve an example; Find the critical speed of mill when the mill diameter is 12 and the diameter of balls is 6. This implies that;

consulter en ligne

颗粒材料元素模拟分析工具Altair EDEM 2020培训材料 - SAG ...

2020年4月12日 Step 3: Define the Geometry Next step is to define the SAG mill geometry used in the model. Import the mill geometry The mill geometry has already been created in a CAD package and is ready to be imported into EDEM. 1. Right click on the Geometries section in the Creator Tree. 2.

consulter en ligne

Mill Critical Speed Calculation - 911 Metallurgist

2015年10月15日 The mill was rotated at 50, 62, 75 and 90% of the critical speed. Six lifter bars of rectangular cross-section were used at equal spacing. The overall motion of the balls at the end of five revolutions is shown in Figure 4. As can be seen from the figure, the overall motion of the balls changes with the mill speed inasmuch as the shoulder ...

consulter en ligne

SAG Mill Grinding Circuit Design - 911 Metallurgist

2016年6月6日 AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the basis for a variety of circuit configurations. ... Many of these mills operate at higher mill speeds (nominally 90% of critical speed) and often use “grid” liners to form an autogenous liner surface. These mills typically grind ROM ...

consulter en ligne

(PDF) Optimisation of the Cadia Hill SAG mill circuit

2001年9月1日 operating mill speed of 74% of critical. SAG mill availability was . expected to be 94%, giving an annual processing rate of 17Mtpa of . monzonite ore. As the deposit contains around 9 percent of ...

consulter en ligne

Optimizing your SAG mill operation - International Mining

2007年3月21日 The amount of pebbles passing through the grate increases with the angle of the grate. It is imperative to ensure the efficient removal of both slurry and coarse pebbles (critical size) in order to ensure the efficient operation of AG/SAG mills. Elimination of the above mentioned material transport problems will allow the mill to respond truly ...

consulter en ligne

Low SAG Mill Critical Speed - 911 Metallurgist

2023年6月23日 If you have to reduce the SAG mill speed because of avoiding liner breakage, maybe it’s better to modify the shell lifter design. Low speed may cause decreasing capacity, higher steel ball and liner wear rate. D80 of SAG mill may be finer because of more cascading action and less capacity which results in more retention time

consulter en ligne

Low SAG Mill Critical Speed - 911 Metallurgist

2023年6月23日 If you have to reduce the SAG mill speed because of avoiding liner breakage, maybe it’s better to modify the shell lifter design. Low speed may cause decreasing capacity, higher steel ball and liner wear rate. D80 of SAG mill may be finer because of more cascading action and less capacity which results in more retention time

consulter en ligne

Semi-autogenous grinding (SAG) mill liner design and

2016年6月6日 78% to 80% critical speed, pulp-lifter efficiencies could fall and affect overall mill performance. Using a smaller, not larger, bucket size to focus the impact of the charge at the toe, along with increasing mill speed as shell lifters wear, is a promising current development in shell liner design and SAG mill opera-

consulter en ligne

SAG mill performance curves for the South Deep

Download scientific diagram SAG mill performance curves for the South Deep mill running at 60, 70 75% critical speed from publication: Milling curves as a tool for characterising SAG mill ...

consulter en ligne

Effect of voltage sags on adjustable speed drives-a critical

1999年3月18日 In this paper, a critical evaluation of the effect of voltage sags on adjustable speed drives (ASDs) is presented. In particular the DC-link voltage variation under voltage sag and its dependence on source impedance, DC-link inductance and output load is computed. It is shown that for larger source impedance, the DC-link voltage

consulter en ligne

EFFECTS OF MILL ROTATIONAL SPEED ON THE BATCH

2021年8月19日 increase of mill speed and optimum speed was not reached in the range of chosen mill speed fractions. Again the rate of breakage was plotted as a function of particle size, the optimum size was 0.8 mm when milling at 30% critical speed. As for 20% and 30% optimum size was not reached. The selection function parameters estimated at

consulter en ligne

SAGMILLING.COM .:. Mill Critical Speed Determination

Result #1: This mill would need to spin at RPM to be at 100% critical speed. Result #2: This mill's measured RPM is % of critical speed. Calculation Backup: the formula used for Critical Speed is: N c =76.6 (D -0.5) where, Nc is the critical speed,in revolutions per minute, D is the mill effective inside diameter, in feet.

consulter en ligne

What is ball screw whip and why does it happen? - Linear

2021年4月23日 The critical speed of a shaft depends on its mass, length and diameter, the amount of deflection it experiences, and the end support method (type of end bearings). The equation for critical speed of a ball screw is: n c = critical speed (rpm) k 1 = factor depending on end bearing arrangement.

consulter en ligne

Effect of voltage sags on adjustable-speed drives: a critical ...

In this paper, a critical evaluation of the effect of voltage sags on adjustable-speed drives (ASDs) is presented. In particular, the DC-link voltage variation under voltage sag and its dependence on source impedance, DC-link inductance and output load is computed. It is shown that, for larger source impedance, the DC-link voltage variation under a voltage

consulter en ligne

en/derivation of critical speed of ball mill samac.md at main ...

Derive Expression Of Critical Speed Of Ball Millrivation for the critical speed of ball mill.A Ball Mill Critical Speed (actually ball,rod,AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its,Online Servers derive expression of critical speed of ...

consulter en ligne

Coordination of horizontal and sag vertical curves on two

2015年7月1日 a driver's speed behavior on critical sag combinations and on suggested sag combinations is different (V T did not show a statistically significant difference, but MSR on the critical sag combinations was significantly higher (+ 5.5 km/h) than MSR on the suggested sag combinations). A similar result was obtained from the comparison of the ...

consulter en ligne

- Machines De Concassage Moulin

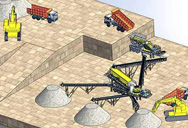

- conception de l'usine de concassage granulats

- broyeur a boulets shemas

- roulant emplois de l opérateur de l usine

- concasseur mobile dolomite de cône Indonésie vendre en afrique du sud

- calcul de la bande transporteuse pour station de concassage

- garde fixe Indonésie la jonction de la bande transporteuse

- carrieres de pierre de beton sable de quartz

- llevar molino bolas bola

- fabricants spirale concentrateurs gisement de marbre

- La Compagnie Des Mines De Charbon De Pt Pipit

- pourquoi moulin de remond pour le meulage réfractaire

- Broyeur Indonésie Sec AppelNouvelle Caldonia Broyeur Indonésie Boulets

- impacto usine de concassage de roches dures

- agence minière en afrique du sud