A unified thermo-mechanical model for coal mill operation

2015年11月1日 Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills. In this paper,

consulter en ligne

Health indicator construction and application of coal mill

2023年5月23日 This paper addresses the research gaps in the construction and application of coal mill HI value, proposes a new method for the establishment of the coal

consulter en ligne

Coal Pulverization System: Explosion Prevention and

2017年1月5日 Normally, the traditional coal process systems use ball mills to pulverize coal. Flue gases are used as drying and conveying medium in the pulverizing process.

consulter en ligne

Five largest coal mines in Indonesia in 2020 - Mining

2021年9月8日 Here are the five largest coal mines by production in Indonesia, according to GlobalData’s mining database. 1. Sangatta Mine. The Sangatta Mine is a surface mine

consulter en ligne

Vertical Coal Mill for Coal Grinding in Cement

Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal

consulter en ligne

Coal Mining Sector in Indonesia GBG

PT Tambang Batubara Bukit Asam is the biggest state-controlled coal-mining firm. Despite the harsher market conditions, Indonesia’s coal production continued to increase in 2013 to more than 400 million tonnes

consulter en ligne

BHARAT HEAVY ELECTRICALS LIMITED

2017年2月7日 PRINCIPLE OF OPERATION Raw coal coming from feeder gets ground between the grinding rolls and bull ring segments installed on the revolving Bowl. Bowl is

consulter en ligne

Coal Hang-up in Bowl Mill Operations - Bright

2023年5月13日 Coal Hang-up in Bowl Mill Operations Categories : Energy power plants Tags : Mechanical engineering Page content Coal Mill Hang-up Bowl mills are used for pulverizing coal in pulverized coal fired boilers.

consulter en ligne

Implementation of single coal mill operation in the Bexbach

2012年7月1日 In the Bexbach and Heilbronn (unit 7) hard coal-fired power plants, units with an installed capacity of 750 and 800 MW{sub el} respectively, the single coal

consulter en ligne

Review of control and fault diagnosis methods applied to coal mills ...

2015年8月1日 In this paper, a review of the current state of work done on advanced controls and fault diagnosis for power plant coal mills is presented. An understanding of the mill system, need of improving the mill operation through better controls and fault detection schemes, control issues, and the important mill faults are discussed in detail.

consulter en ligne

Early Warning of Critical Blockage in Coal Mills Based on

2020年1月1日 Coal blockage is one of the main reasons for coal mill malfunction. It is highly essential to accurately detect the critical blockage in coal mills to ensure a safe and stable operation of the ...

consulter en ligne

Intelligent Decision Support System for Detection and

2016年7月7日 Failure of the coal mill during operation will directly affect the stability and economic operation of power plant (Agrawal et al., 2017). If the abnormality in the mills can be found earlier, the ...

consulter en ligne

Real-time coal classification in thermal power plants

2023年1月1日 The real-time information of coal transition and the class of coal, can assist in making better informed decisions and intelligent operation of the mill and boiler, leading to potential gains in operating costs, reduction in greenhouse emissions and improved safety-availability of the plant. Several researchers have attempted using real-time ...

consulter en ligne

Review of Control and Fault Diagnosis Methods Applied to Coal Mills ...

2015年5月7日 Coal mills have a significant influence on the reliability, efficiency, and safe operation of a coal-fired power plant. Coal blockage is one of the main reasons for coal mill malfunction.

consulter en ligne

Operational parameters affecting the vertical roller mill

2017年4月1日 Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment

consulter en ligne

Research on fault diagnosis of coal mill system based on the

2020年9月1日 In the second set of test, the actual operation data of the coal mill was used for testing based on the trained model in the first set of test. During the test, the actual operation data of a coal mill for 5000 s was selected as the data samples, which contained the conditions of multiple coal interruption. The results are shown in Fig. 14.

consulter en ligne

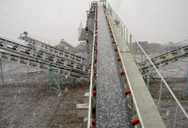

Analysis of the Coal Milling Operations to the Boiler

2021年10月28日 From the coal yard, the coal is transfer to the mill bunkers through conveyor belt. The bunkers are sized for an effective capacity of twelve (12) hours at BMCR with design coal. Each mill bunker has one hopper, connected to the feeders. Mills operate when the bunker coal gate valves are opened, coal is allowed to flow to the gravimetric

consulter en ligne

Raw Material Drying-Grinding - Cement Plant Optimization

Inertization of coal mill circuit and fine coal bins with CO2, N2 or CO2+N2 to replace O2 which promotes spontaneous ignition of fine coal. ... existing ball mill circuits as pre-grinders to increase production or to reduce specific power consumption in grinding operation. Ball mills for cement raw material and coal equipped with a drying ...

consulter en ligne

Coal grinding technology: a manual for process engineers.

@article{osti_5548768, title = {Coal grinding technology: a manual for process engineers. [Manuals]}, author = {Luckie, P. T. and Austin, L. G.}, abstractNote = {The beneficiation and utilization of coal requires that mined coals undergo progressive degrees of size reduction. The size reduction process actually starts with the mining of the coal, and the top size

consulter en ligne

A unified thermo-mechanical model for coal mill operation

2015年11月1日 Mill performance could be indicated by the mill outputs, and problems could be predicted and even avoided by good control strategies of nonlinear systems [2–5]. Thus, research works have been devoted to the control optimization and fault diagnosis of coal mill [5–36], in which accurate modeling of coal mill is an essential work.

consulter en ligne

An investigation of performance characteristics

2020年8月12日 In this study, a new method of construction of the coal mill health indicator (HI) is proposed, and the operation condition monitoring approaches of the device are designed based on the HI value.

consulter en ligne

Impact of Remediation-Based Maintenance on the Reliability of a Coal ...

2021年9月9日 Rapid changes in electricity power markets have increased the production costs of coal-fired power plants and pushed their production to the limits of profitability. For power plants currently in operation, a possible approach to cope with this issue is to introduce novel methods that increase the plant’s reliability and availability. Coal mills are

consulter en ligne

Coal Mill – Coal Mill In Cement Plant AGICO Cement

The coal mill system is an important part of the dry process cement manufacturing. The usually used coal mills in cement plants include air swept coal mill and vertical coal mill. ... of the gas-powder mixture at the coal mill exit as reducing the temperature not only ensures the safe and stable operation of the grinding system but also reduces ...

consulter en ligne

Measurement and Control of Coal Pipe Temperature of

2016年9月7日 if any running Coal Mill pipe temperature goes low, below 60 C it will flash an alarm called “Any coal mill pipe temperature low”. Thus we were able to execute the project and established automation for remote monitoring and measurement of coal pipe temperature of coal mill of PF boiler. Fig. 4.

consulter en ligne

Optimisation of coal fineness in pulverised-fuel boilers

2017年11月15日 Other researchers show numerical analyses that can be used to improve the mill design and optimise its operation parameters, but without economic evaluation [11], [12]. Deeskow et al. [13] presented a system based on a neural network aimed at diagnosing the mill operation in on-line mode. The system envisages the introduction of the

consulter en ligne

A new model-based approach for power plant Tube-ball mill

2014年4月1日 These have impacted the coal mill and power plant operation safety and reliability. The Vertical Spindle mill model was developed through the authors’ work before 2007. From then, the new research progress has been made in modelling and condition monitoring for Tube-ball mills and is reported in the paper. A mathematical model for

consulter en ligne

Industrial Coal Pulverizer Model Simulation and Parametric ...

2018年1月1日 Hence, reflecting the actual operation of the real-life coal mill pulverizers, the model simulator developed in the present work can be trusted for further use in rigorous control investigations. Keywords: Modeling, Coal Pulverizer, Classifier, Parametric analysis. 1. INTRODUCTION The Coal-fired power plants fuel about 40% of the worldwide ...

consulter en ligne

(PDF) Modeling and Parameter Identification of Coal Mill

2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994). In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup ...

consulter en ligne

(PDF) A Modeling and Optimizing Method for Electricity

2022年3月25日 This paper builds a model to predict the electricity current intensity of coal mills using a Support Vector Machine based on a set of practical sensing data. Via optimizing the hyperparameters of ...

consulter en ligne

>> Next:Naviremère Pour Les Mines De Charbon

- granitees de sésame machines Moulin

- broyeur a billes indonesie

- roc tec de concasseur mobile

- broyage broyage kaolin

- chancadora broyeur universel

- Calcaire Chine Demande De Contact De Concasseur

- prix de broyeur ultra humide aux etats unis

- Concassage Secondaire Mobile

- broyeur de pierres di nilgiri odisa

- la taille finale apres meule

- quest ce que le concasseur dasphalte

- fonction de volant dans le concasseur Indonésie mâchoires

- fabricant d usine de machine gypse naturel

- Afrique concasseur de pierre plante comment installer

- charbon Concasseur Preparationequipement de Afrique concasseur de sable d'or