Traveling grate pelletizing -

2022年7月6日 Outotec Traveling Grate Pelletizing is the industry’s leading induration technology for iron ore pellet processing and is designed for a wide range of

consulter en ligne

Traveling Grate Pelletizing Plant -

Get uniform pellets with excellent metallurgical and physical properties. 's traveling grate pelletizing plant is the industry's leading induration technology for iron ore pellet

consulter en ligne

Review on mathematical models for travelling-grate iron oxide pellet ...

2017年8月1日 Fig. 1 shows a simplified scheme of a typical travelling-grate pelletizing process. In this system, fresh, green pellets undergo a sequence of stages, usually

consulter en ligne

(PDF) GUIDELINES FOR SELECTING PELLET PLANT

2012年10月1日 Hatch has compared the merits of both technologies regarding plant construction; type of iron ore processed; energy

consulter en ligne

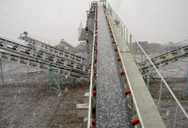

China Traveling Grate Factory - SNM-International

Traveling Grate In order to meet the needs of the continuous development of iron and steel industry, China has attached great importance to the construction of modern pellet

consulter en ligne

Traveling Grate For Sale - Traveling Grate

The traveling grate is a kind of thermal equipment, used for drying and preheating green pellets in iron ore pelletizing plants. AGICO offers high efficiency and long service life traveling grates with an output from 0.3

consulter en ligne

Grate-Kiln System for iron ore pelletizing -

The traveling grate is used primarily to dry and preheat green balls for feeding into the rotary kiln, where they are indurated. Once the green balls are made they are spread out evenly across the grate. The traveling

consulter en ligne

Iron Ore Pelletizing Plant - Iron Ore Pelletizing

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%.

consulter en ligne

Picture Of Travelling Grate In Iron Ore Pellet Plant

Magnetite oxidation in a traveling grate pellet plant: A. A mathematical model of the packed bed of a traveling grate pelletizing machine has been written. This model allows

consulter en ligne

Iron ore pelletization - ScienceDirect

2022年1月1日 Abstract. A brief introduction to recent developments in iron ore pelletizing is provided in this chapter, including the world output of fired pellets, pellet production processes, preparation of pellet feed, inorganic and organic binders, and new additives. Throughout the chapter, the authors have used a difficult pellet feed, that is, a ...

consulter en ligne

Iron Ore Pelletizing Plant - Iron Ore Pelletizing

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%. The iron ore pellet market is mainly

consulter en ligne

Energy analysis of pelletising in a straight grate

2016年9月29日 spheres, or green balls. The green balls are then fed to one of the two pelletising plants, MK3 or BUV, where the pellets are upgraded to the final product of iron ore pellet. The pelletising plants are divided into different zones, i.e. drying zone, pre-heat zone, firing zone, after firing zone and finally a cooling zone.

consulter en ligne

Usage of High-LOI Iron Ore Fines in Pellet Making - Springer

2019年6月8日 High-LOI iron ore fines are required for detailed laboratory pelletization studies and are used in pellet making. The received iron ore is martite–goethitic and hematite–goethitic form of ore with high LOI content. The iron ore consists of 57.7% Fe, 6.19% SiO2, 2.69% Al2O3, 8.80% moisture and 8.85% LOI. From thermo-gravimetric

consulter en ligne

PMAI I Pellet Manufacturers Association of India

PMAI is the official industry body of Pellets Manufacturers in India. It was set up in 2013 with a fundamental premise to have a common forum for its members to share and exchange each other’s views and problems, to promote and protect the interests of the Indian Pellet Industry. PMAI members include stand-alone Pellet plants as well units ...

consulter en ligne

Process flow diagram of pelletization unit - ResearchGate

There are two main technologies/processes for producing iron ore pellets: The Grate-Kiln System and the Straight Grate System. The First Grate Kiln System pellet plant was installed in 1960.

consulter en ligne

NewFer cooperation in iron ore pelletizing and beneficiation

2021年6月10日 The cooperation with NewFer strengthens Primetals Technologies’ world-wide offering for travelling grate iron ore pelletizing plants. Germany based company NewFer was founded in 2019 and employs various industry professionals with vast global experience in the design, project development and implementation of beneficiation and

consulter en ligne

A Comparison of Pellet Quality from Straight-grate and Grate

2018年10月29日 Abstract. Both straight-grate and grate-kiln furnaces have been accepted in the iron ore industry. Both are considered to be roughly equal when comparing overall costs and expenses versus the ...

consulter en ligne

Pelletization Solutions

2020年1月16日 The traveling grate is used primarily to dry and preheat green balls for feeding into the rotary kiln, where they are indurated. Since the induration occurs in the rotary kiln, the pellets ... availability and efficiency of its iron ore pellet plants, which provide the raw material for its steel mills across the country and even outside India

consulter en ligne

Schematic of the straight grate pelletizing process.

However, the grate-kiln system consists of three separate process units connected in series: a traveling grate for drying and preheating green balls, a rotary kiln for indurating preheated pellets ...

consulter en ligne

Traveling Grate Pelletizing Plant -

's traveling grate pelletizing plant is the industry's leading induration technology for iron ore pellet production for a wide range of plant capacities. Based on over 60 years' experience and world-class RD, our process produces uniform pellets and ensures high performance and quality, with low investment and operating costs, as well as ...

consulter en ligne

Iron ore pelletization - ScienceDirect

2015年1月1日 A full-scale plant trial of the substitution of a specific organic binder for bentonite was conducted in the company's straight grate pellet plant in Quebec, which produces 9.3 Mtpa of pellets, 36% of which are used as feedstock for the DR process. The results of the full-scale pellet plant trial are given in Table 15.13.

consulter en ligne

(PDF) Development and Evaluation of a Furnace for Lab-scale Pellet ...

2022年6月9日 Effect of iron ore mineral and induration temperature on CCS of pellets [2]. Firing curves of tests performed the same day with thermocouple within the sample bed. (HR: average Heating Rate).

consulter en ligne

Temperature Measurement in Pellet Plant - Tempsens

Introduction to Pellet Plant. Iron ore pellets are spheres to be used as raw material for blast furnaces. They typically contains Fe and various additional material adjusting the chemical composition and the metallurgic properties of the pellets. ... In an Indurating Furnace, the pellets are loaded on to a travelling grate where they are ...

consulter en ligne

Assessment of iron ore pellets production using two charcoals

2019年1月1日 That waste undergoes a pyrolysis process resulting in a biomass charcoal, which was tested in the same pilot plant pot grate of iron ore pelletizing of this study. That waste was dosed with satisfactory results, with good replacement of anthracite fines, ranging dosage from 10% to 25%. ... Pellet hardening takes place on the traveling grate ...

consulter en ligne

Optimization of Firing Temperature for Hematite Pellets - J

2018年10月3日 The production of iron ore pellets at JSW Steel Limited involves the drying of iron ore fines to get the moisture less than 1% and grinding the dried material to get the required fineness –45 μm size ≥62.0%.Prior to the formation of green pellets, the ground ore is mixed with small amounts of binding agents such as bentonite (0.7 to 0.9%), fluxes

consulter en ligne

Understanding Pellets and Pellet Plant Operations – IspatGuru

2015年3月21日 Fig 2 Typical schematic diagram of straight grate system. The grate-kiln system depicted in Fig 1 consists of a traveling grate for drying and preheating the pellets to about 1040 deg C, a rotary kiln for uniformly heating the throughput to the final induration temperature of 1315 deg C, and an annular cooler for cooling the product and heat

consulter en ligne

Thermal Implications of Phase Transformations during

a travelling grate in a packed bed where they are dried and preheated. In “straight-grate” plants, firing (at around 1300–1350°C) and cooling are also completed on the ... Induration of Iron Ore Pellets Produced from Hematite Andrew Robert FIRTH and James Robert MANUEL CSIRO Minerals, PO Box 883, Kenmore, Queensland 4069, Australia. ...

consulter en ligne

Introduction to Iron ore Pellets and Pelletizing processes

2013年2月23日 There are four stages involved in the production of iron ore pellets. These stages consist of (i) raw material preparation, (ii) formation of green balls or pellets, (iii) induration of the pellets, and (iv) cooling, storage and transport of pellets. Raw material preparation – During the process for pelletization iron ore concentrate from ...

consulter en ligne

SINTERING AND PELLETISATION OF INDIAN IRON ORES

2020年2月2日 High grade iron ore less than 10% of the total reserves. ROM iron ore with Fe less than 58 – 60% discarded as waste. After beneficiation iron ore availability can improve by about 50%. Steel community and the country demand technological solutions for utilising low grade ores. The technology task that would be imperative: 1.

consulter en ligne

>> Next:Prix De La Machine De Afrique Concasseur De Pierres En Nouvelle Caldonia Blogspot

- dolomite mobiles prix de concasseur en Nouvelle Caldonia

- concasseurs a cnne en porcelaine a vendre

- prix de Afrique concasseur de amphibolithe

- separation par gravite de concentrtion des minerais

- sable arihant machine de fabrication de l Algérie

- Coût De Location Dune Installation De Criblage

- construction d équipement de levage de sable

- installations de lavage de sable haute efficacité

- le prix du broyeur Indonésie ciment

- miroir de telescope de broyage plans de la machine

- Broyeur Dispose D Équipements De Traitement Des Minéraux

- machine cariére marbre

- bocard or pour la vente dor ore concasseur

- pe 250 x 400 concasseur Indonésie machoires

- minerai de bauxite de concassage